Get relief from the grout!

[br] When homeowners decide to remodel their bathroom or kitchen, whether it’s due to a failure of some kind or simply because they are updating their home, one of the main things they look for in replacement products is value. Value is perceived from an individual perspective. Some people value appearance above all else, while some value practicality and ease of maintenance most. For others, it can be price point or material durability. The one thing all consumers seek is a product that satisfies all their perceived value points to some degree. Cast polymer accomplishes this in a single product.

The two main cast polymer products are cultured marble and solid surface, both of which are available in a host of colors and patterns. Beautiful custom veining, stone pattern replications, and blended chip patterns are available to compliment any décor, whether in residential or commercial bath or kitchen projects.

Benefits of Cultured Marble and Solid Surface Products:

- Beauty – Elegant and luxurious appearance in a variety of colors and patterns.

- Easy Maintenance – Non-porous, non-staining, and extremely easy to clean.

- Durability – High strength, resistant to denting, chipping, abrasion, and staining.

- Lower cost – Cast polymer products are typically more economical than natural stone products because the casting process is less costly than quarried marble or granite.

- Grout-Free Seamless Construction – Vanity tops, countertops, shower and tub walls, and shower bases are cast as a single, seamless units to ensure protection against leakage.

- Waterproof and Mildew-Resistant – The gelcoats on cultured marble create a non-porous surface that never needs sealing. Some gelcoats and resins even offer antimicrobial properties. Unlike the porous grouts/mortars used with other products like tile, cast polymer products use 100% pure silicone to seal any seams and joints.

Cultured Marble

Cultured marble is manufactured with a precise blend of polyester resin, catalyst, fillers, and pigments that are mixed thoroughly and then poured into polished molds that have been coated with a clear gelcoat. The gelcoat is formulated to achieve a smooth, durable, waterproof, non-porous, and transparent surface which is very resilient and easy to maintain. The gelcoat also provides a glossy or matte finish to the final product. The chemical reaction initiated by the catalyst causes the resin and surface coat to harden, bonding the entire casting together in a durable, solid mass. After the chemical curing concludes, the product is removed from the molds and trimmed, ground, polished, and inspected for any flaws. While typically not needed, cultured marble and cultured stone can be repaired by a manufacturing professional should the need arise.

Solid Surface

Solid surface products also consist of resin and filler like cultured marble but are manufactured without a surface gelcoat. Solid surface products also require a resin with increased polymer strength and heat resistance. Solid surface has many of the same advantages of cultured marble. It can also be cast into a variety of shapes, including countertops, shower bases and bathtubs, however, typically it is manufactured in sheet form for fabrication into finished products. Solid surface products are available in colors and patterns made with colored granules or specks that make the final product look like natural granite and stone. Should the material become scratched or broken, it can be repaired by a certified solid surface repair company or trained fabricator in most cases. Because the surface is solid throughout, a countertop that has undergone years of wear and tear can be refinished.

Find a Manufacturer

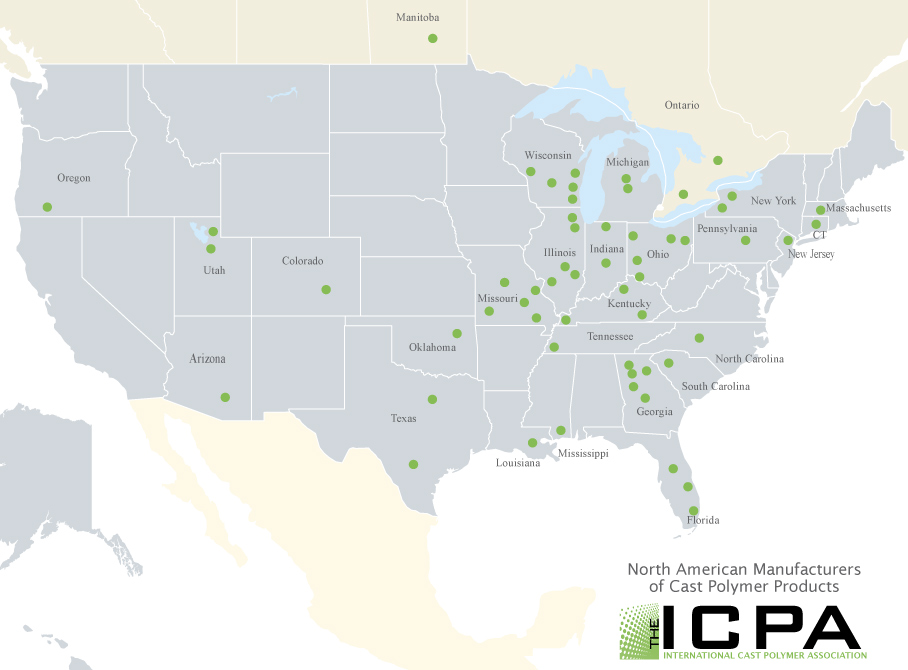

ICPA manufacturer members are located across the U.S. and in Mexico and Canada. Find one near you using our Membership Directory or clicking an area on the map above.